Galvanized Triangular Joining Plate for Solar Panel Mounting

FOB Price | 1,000 pieces (Min. Order)

Custom specifications and OEM service available

Related Products

Product Description

Triangular Joining Plate – Hot-dip galvanized steel solar mounting bracket manufactured in China. Features multi-hole design for 15°/20°/25° roof angles and reinforced stamped steel construction. OEM/ODM available with CE/TUV certification. Compatible with standard rails & hardware for commercial PV installations.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | Galvanized Triangular Joining Plate |

| Material | Reinforced Stamped Steel, Hot-dip Galvanized |

| Structure Type | Bent triangular plate structure |

| Common Angles | 15° / 20° / 25° (customizable) |

| Mounting Position | Between roof and rail beam |

| Hole Layout | Multi-hole design for versatile mounting |

| Compatible Hardware | Rails, nuts, base components |

| Installation | Pre-drilled holes for standard bolts |

Applications

Connects solar rails on rooftops/commercial arrays. Adjustable for 15°-25° angles. Works with IronRidge, Unirac, Schletter systems.

PV Mounting Systems

Triangle link between rails and vertical posts in ground-mount and rooftop solar installations. Provides secure structural connections.

Flat Roof Installations

Fixed angle mounting for commercial and residential rooftop solar systems. Optimizes sun exposure for maximum energy production.

Carport Structures

Angled mounting brackets for solar carport and parking structure installations. Ensures proper panel orientation.

Commercial Solar

Perfect for commercial rooftop solar installations. Offers reliable structural support and optimal tilt angles.

Residential Solar

Ideal for residential rooftop solar systems. Provides secure mounting with customizable tilt angles.

Agricultural Solar

Supports agrivoltaic systems combining solar energy with agricultural activities. Durable for outdoor farming environments.

Certifications

Our products meet international quality standards and certifications:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management

- DIN 934 / ISO 4032 Standards Compliance

- ANSI B18.2.2 American Standards

- Third-party testing and certification

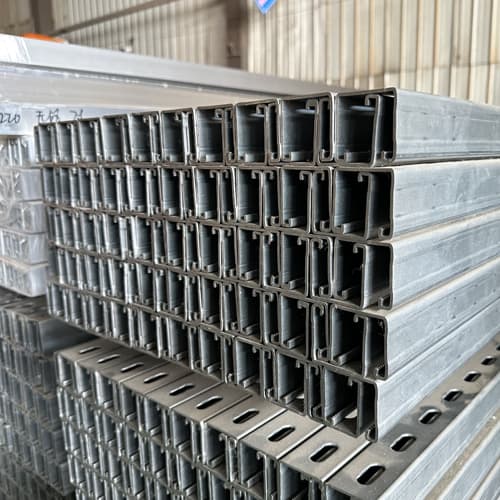

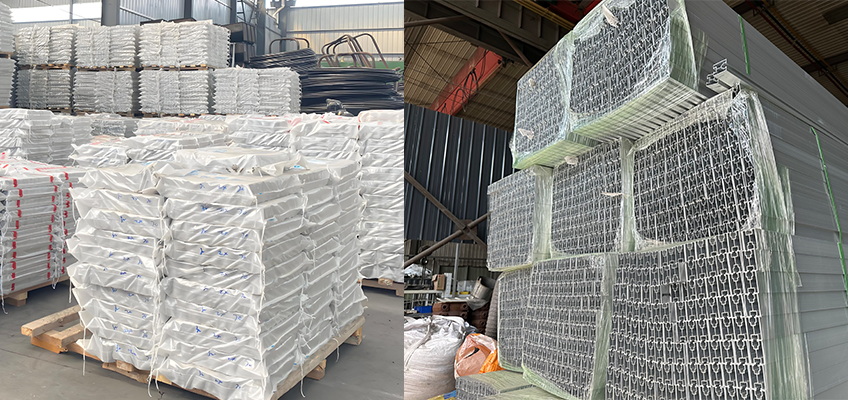

Packaging

Professional packaging solutions for safe transportation:

- 25kg cartons with inner plastic bags

- Custom branded packaging available

- Barcode and QR code labeling

- Moisture-proof and anti-corrosion protection

- Stackable design for efficient storage

Company Introduction

Welcome to Hebei Zixian Fasteners Co., Ltd. – Your Reliable Manufacturer of Galvanized Fasteners and Solar Mounting Accessories from China!

What we offer:

- Full in-house production – from raw materials to packaging

- Solar mid clamps, end clamps, brackets, galvanized bolts & nuts

- ISO-compliant quality control

- Competitive pricing & fast delivery

- OEM & custom fastener solutions for B2B buyers

Contact us today for product catalogs, samples, or quotes:

- Website: zixiansolarparts.com

- Email: xzi675763@gmail.com

- WhatsApp: +86 15630389170

Frequently Asked Questions

1. What are the advantages of using hot-dip galvanized triangular joining plates for large-scale solar farms?

Our hot-dip galvanized triangular joining plates offer superior corrosion resistance, essential for utility-scale projects in coastal or high-humidity regions. The reinforced stamped steel construction ensures 25+ year lifespan while supporting heavy snow/wind loads.

2. Can you customize triangular solar mounting plates for non-standard roof angles?

Yes, as a Chinese manufacturer we regularly produce custom-angle joining plates (30°, 45° etc.) with same-day prototyping. Our engineering team can adjust hole patterns and material thickness to match your rail system specifications.

3. What certifications do your triangular solar brackets have for international projects?

All plates come with CE/TUV/SGS certifications and full traceability documentation. We’re ISO 9001 certified factory with 12 years experience supplying to European and North American EPC contractors.

4. How does your multi-hole design improve installation efficiency for solar installers?

The patented multi-hole layout allows ±15mm position adjustment during installation, reducing alignment time by 30% compared to fixed-hole brackets. This is particularly valuable for large teams working on tight deadlines.

5. What’s the MOQ for OEM triangular joining plates with company branding?

Standard MOQ is 5,000 pieces but we accept trial orders of 1,000 pieces for new partners. Laser engraving, custom packaging and private labeling available with 2-week lead time.

6. Why should we choose your factory over other Chinese triangular bracket suppliers?

We operate dedicated solar mounting production lines (not shared with other products) with monthly 500,000pcs capacity. All shipments include material test reports and our 10-year warranty covers material defects.

7. Do you provide CAD drawings for triangular connecting plates before bulk production?

Yes, we’ll provide DXF/DWG files within 24 hours for your engineering team’s approval. Can also adapt designs to match IronRidge, Schletter or other major system profiles.

Get in Touch

We’ll contact you within 24 hours after submission. For immediate assistance, use the direct contact methods below.

Why Choose Us?

- ✓ 1-on-1 Expert Support – Custom solutions for your specific needs

- ✓ Factory Tours Available – Verify our quality standards in person

- ✓ Global Supply Experience – Trusted by clients in 15+ countries